Quality Assurance

High Chrome product superiority is achieved and maintained by a constant quest for quality and value engineering at Welcast.

Product operations are continuously and closely monitored. Quality assurance begins at the root level by employing the optical emission vacuum spectrometer with computer control for instant analysis of molten metal.Casting is done in moulds with sand prepared and tested fully. The microstructure of casting is constantly photographed with the help of an electronic microscope and camera.

Welcast's quest for quality is supported by a Research and Development Wing manned by dedicated metallurgists and technicians who work to maintain the high quality standards.

High performance longer lasting

Welcast Grinding Media is a combination of high performance and durability. It strikes a perfect balance between hardness and toughness. As a result thousands of tons of Grinding Media is currently employed in Indian and International industries without a single failure.

Grinding Media Quality

For over more than four decades, WELCAST has had a tradition of supplying the finest quality cast high chromium grinding media to the cement industry. WELCAST's knowledge of foundry processes, heat treatment and application has been essential to this tradition. WELCAST balls consist of a martensitic matrix and 76 Rockwell C hardness chromium carbides (25-40 %). This structure provides shock resistance and is the main deterrent to wear. Specific matrix hardness, carbide distribution, and microstructure are designed for each individual application.

Selection of the Alloys

The mill's working conditions are important factors in determining the most suitable alloy for any given application. Because mill parameters and grinding conditions vary considerably,

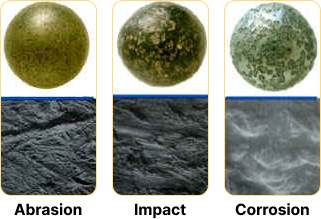

the primary wear mechanisms also vary, these primary wear mechanisms are Abrasion, Impact and Corrosion.

WELCAST uses a marked ball test procedure to determine which wear mechanisms are dominant. Balls are marked by drilling identification holes into them and are then brought to identical weights. After operating in a full-scale mill for a period of time, these test balls are recovered and reweighed.

Their weight loss per unit of surface area is then calculated. This specific wear rate is used to compare various WELCAST alloys to the grinding media currently being used.